Hastelloy Sheets Plates| Manilaxmi Industrial

In terms of High Performance Hastelloy Sheets Plates are nickel-based alloys that are used by manufacturers for their ability to provide exceptional Corrosion Resistance.

We Manilaxmi Industrial are one of the leading Hastelloy Sheets Plate Supplier in India who provide sheets and plates of Hastelloy of high quality delivered as per your requirements.

More importantly, our aim is to provided your business manufacturing solutions that you cannot refuse. Since they are tailored to generate maximum profits you heart desires.

What are Hastelloy Sheets Plates?

It is to provide Superior strength to appliances and ensure that your manufacturing business delivers High Performance under extreme environment that Hastelloy Sheets Plates is used. These are nickel-based alloys designed to tolerate processing like pitting, oxidation, and stress corrosion cracking.

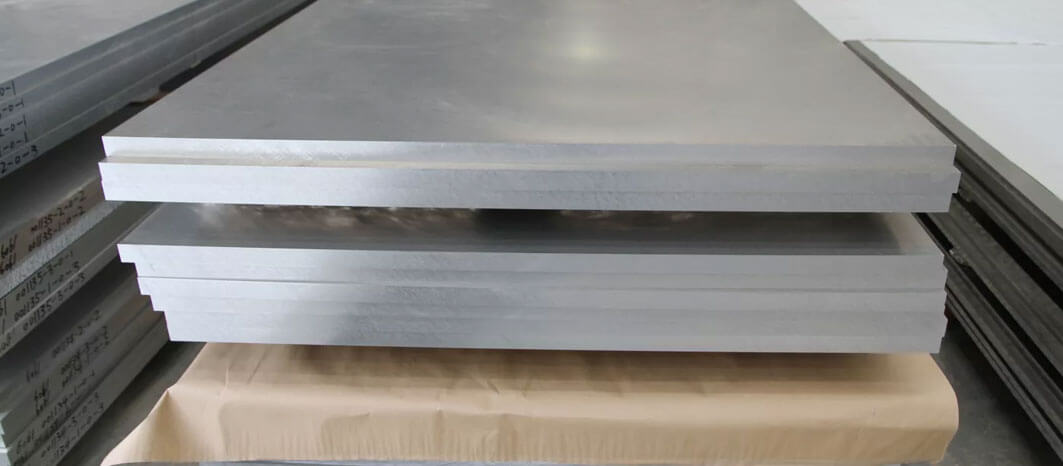

Hastelloy Sheets vs Hastelloy Plates

|

Type |

Description |

Thickness Range |

Uses |

|

Hastelloy Sheets |

They are nickel-based alloy sheets that are thin, flexible, and corrosion-resistant |

Typically, ranges from 0.5 mm to 6 mm |

Proves to be useful in heat exchangers, chemical processing, aerospace components, marine systems, and medical equipment |

|

Hastelloy Plates |

These are high-strength alloy plates designed for extreme environments |

Usually, they measure 6 mm and above |

They are commonly used in pressure vessels, reactors, structural supports, high-temperature applications, and heavy industrial machinery |

Types ofHastelloy Sheets Plates:

It is in four major groups that Hastelloy Sheets Plates can be classified into. They are as given below:

- Grading Basis:

Typically, Hastelloy Sheets Plates are graded according to their ability to withstand harsh environment.

- Manufacturing Process:

Hastelloy Sheets Plates is also classified as per the method used to manufacture them. Typically, it includes Hot Rolling and Cold Rolling.

- Surface Finish:

According to the type of surface finish used Hastelloy Sheets Plates are also classified.

- Applications Used:

Hastelloy Sheets Plates can also be classified according to the applications they are used. For example, Aerospace Hastelloy Sheets, Industrial Hastelloy Plates, Medical-Grade Hastelloy Sheets, and Marine-Grade Hastelloy Plates

Hastelloy Sheets Plates Standard and Specifications:

|

Standard Specification |

Description |

|

ASTM B575 |

It is a standard for most nickel-molybdenum-chromium alloys. So, be it in the form of sheet, plate, or strip. |

|

ASME SB-575 |

This is a standard for pressure vessel. It is ASME equivalent of ASTM B575 |

|

AMS 5540 |

Typically, a standard for high temperature alloy sheet/plate |

|

UNS N10276 |

It is a standard numbering system for Hastelloy C276 |

|

UNS N06022 |

The Hastelloy C22 standard numbering system |

|

EN 2.4819 |

It is an European standard for corrosion-resistant alloys |

|

ISO 6208 |

An international standard for all nickel-based corrosion-resistant materials |

|

DIN 17750 |

It is a German standard set for high performance alloys |

Hastelloy Sheets Plates Manufacturing Process:

There are several steps involved in the manufacturing of Hastelloy Sheets Plates. They are as follows:

- Firstly, high-quality mix of nickel, molybdenum, chromium, iron, and cobalt are selected. They are then melted in an electric arc furnace (EAF) or vacuum induction furnace (VIM). This is done to ensure that the impurities in the metals are eliminated and a homogenous mixture is formed.

- The molten form of Hastelloy Sheets Plates is to be poured into ingot molds or continuous casting machines. They are then allowed to cool down to improve structural integrity and reduce internal stress

- The slabs formed after Melting Moulding is then reheated above 1,200°C. They are then passed Hot Rolling Mills. The result is production of a Hot Rolled Hastelloy Plate

- In case thin sheets of Hastelloy is required then the hot rolled Hastelloy Plate is treated using cold rolling process at room temperature. This procedure helps in enhancing surface finish and mechanical strength

- To improve Corrosion Resistance and provide it relief from stress Hastelloy Sheets Plates are exposed to solution annealing at temperature ranging from 1,100–1,150°C

- The Titanium Sheets Plates are then treated with Pickling in acid bath to eliminate oxides that may have formed during heat treatment

- Titanium Sheets Plates are then cut into customised sizes and shapes as per requirements. Usually, processes like shearing, laser cutting, plasma cutting, or water jet cutting are used

- The product then undergoes strict quality testing. They usually include mechanical examination, chemical analysis, microstructure exam, corrosion resistance test, and ultrasound or radiographic inspection

- Finally, Titanium Sheets Plates are well-packed using protective films to avoid damage and ensure safe delivery before despatching them. Usually, the material used include wooden crates, pallets, or protective wrapping.

Hastelloy Sheets Plates Weight Chart:

|

Thickness (mm) |

Weight per Square Meter (kg) |

Weight per Square Foot (kg) |

|

0.5 mm |

4.34 – 4.62 |

0.40 – 0.43 |

|

1.0 mm |

8.69 – 9.24 |

0.81 – 0.86 |

|

1.5 mm |

13.03 – 13.86 |

1.21 – 1.29 |

|

2.0 mm |

17.38 – 18.48 |

1.62 – 1.72 |

|

3.0 mm |

26.07 – 27.72 |

2.42 – 2.57 |

|

4.0 mm |

34.76 – 36.96 |

3.23 – 3.44 |

|

5.0 mm |

43.45 – 46.20 |

4.03 – 4.29 |

|

6.0 mm |

52.14 – 55.44 |

4.84 – 5.15 |

|

8.0 mm |

69.52 – 73.92 |

6.45 – 6.87 |

|

10.0 mm |

86.90 – 92.40 |

8.06 – 8.58 |

|

12.0 mm |

104.28 – 110.88 |

9.68 – 10.30 |

|

15.0 mm |

130.35 – 138.60 |

12.11 – 12.89 |

|

20.0 mm |

173.80 – 184.80 |

16.13 – 17.16 |

|

25.0 mm |

217.25 – 231.00 |

20.16 – 21.44 |

Hastelloy Sheets Plates Uses:

Hastelloy Sheets Plates are used in a wide range of industries that involve highly corrosive, high-temperature, and extreme environments. They are follows:

- Chemical Processing

- Aerospace and Aviation Industry

- Marine and Offshore

- Power generation and Energy Industry

- Medical and Pharmaceutical Industry

Difference between Hastelloy Sheets Plates

|

Property |

Hastelloy Sheets |

Hastelloy Plates |

|

Thickness |

Usually measures less than and not equal 6 mm |

It measures greater than 6 mm |

|

Strength Durability |

Strong yet used applications requiring lighter weight |

Offers great strength |

|

Weight |

Lightweight due to its reduced thickness |

Has greater thickness therefore heavy |

|

Flexibility |

Increased flexibility |

Rigid and retains shape under heavy load |

|

Common Uses |

Aerospace, chemical processing, medical equipment, heat exchangers |

Reactors, pressure vessels, and structural applications |

|

Manufacturing Process |

Produced by cold rolling for better surface finish |

Manufactured using hot rolling to improve strength |

Why choose Manilaxmi Industrial Hastelloy Sheets Plates?

At Manilaxmi Industrial, a leading Hastelloy Sheets Plates Producer in India, we offer your business high-quality Hastelloy Sheets Plates at affordable cost. Given below are a few reasons why you should choose Manilaxmi Industrial as your preferred manufacture supplier for your business:

✅ Use of Premium Quality Materials

✅Following Industry Standards Compliance

✅ Provision of Customization Precision

✅ Offering attractive competitive pricing Fast Delivery

✅ Availability of Expert Support Quality Customer Care

Contact today Manilaxmi Industrial, The Hastelloy Sheets Plates Supplier You Can Trust:

For premium Hastelloy Sheets Plates available at affordable pricing, Manilaxmi Industrial, your partner is here to delivers for your business high-quality alloys. Please contact us today to get expert guidance, competitive pricing, and on-time delivery of Hastelloy Sheets Plates catered to fulfil your needs.